|

|

|

TRUCK UNDERRIDE HAZARDS

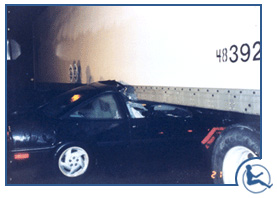

Truck underride is when a passenger vehicle crashes into and penetrates beneath, or "underrides", the taller rear or side of a large truck or trailer. The top of the car is crushed or ripped off, and the occupants suffer severe head trauma or may be decapitated. Rear guards on trucks and trailers were initially required in 1953, and are known as ICC bumpers (Interstate Commerce Commission), but such rear bumper devices are typically defective.... too high above the road, too narrow across the truck's rear, and too weak to prevent the underride hazard. Truck underride is when a passenger vehicle crashes into and penetrates beneath, or "underrides", the taller rear or side of a large truck or trailer. The top of the car is crushed or ripped off, and the occupants suffer severe head trauma or may be decapitated. Rear guards on trucks and trailers were initially required in 1953, and are known as ICC bumpers (Interstate Commerce Commission), but such rear bumper devices are typically defective.... too high above the road, too narrow across the truck's rear, and too weak to prevent the underride hazard.

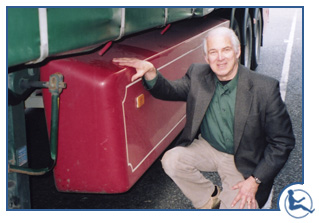

A safer rear guard is lower, full-width, and stronger. The guard should be about 16 inches above the road, to engage the frontal structures of even the smallest cars, and wide enough across the entire rear of the truck, and strong enough so it won't break away, with supports at the rear corners of the trailer. After 30 years of industry delay and politicizing, and stimulated by a Congressional Hearing in 1991, NHTSA finally issued a safety standard to require safer guards, but only for new trailers effective as of January 1998. All pre-1998 trailers and large trucks already on the road, and all new trucks after that date, are still not covered, and may well be defectively designed and ineffective.

About 40-percent of all rear underride fatalities involve the rear corners of the truck or trailer. Therefore, an effective guard should have additional vertical support members at the corners to help prevent the main horizontal bar from breaking away and failing. Such vertical supports at the corners will also help deflect the car and thereby keep the car's upper passenger compartment and roof from being ripped into by the trailer's sharp rear corners that are typically around 40 inches above the ground.

Coal-carrying dump trucks typically have over-extended truck bodies that act as a lethal rear overhang, yet there is typically no rear underride guard at all. There has been a continuing epidemic of fatal underride crashes, particularly in Kentucky, in which slow-moving coal dump trucks are rear-impacted in the dark of night. Many of these coal trucks have only two small tail-lights that are concealed too far forward beneath the extended long bed of the coal truck body, and as these loaded coal trucks travel very slowly up the curving mountain roads, the oncoming driver behind the truck can't react in time.

Side underride accounts for almost half of the annual toll of about 500 fatalities, yet there has been no action by NHTSA or the trucking industry to require side underride prevention guards. Many European nations adopted side underride guards, beginning in the mid-1980's, and they were originally intended to stop bicyclists, motorcyclists, and pedestrians from becoming entrapped under the sides of trucks. Yet, such side guards have proven to also work well to stop cars from continuing beneath the sides of the large trucks and trailers. Side underride accounts for almost half of the annual toll of about 500 fatalities, yet there has been no action by NHTSA or the trucking industry to require side underride prevention guards. Many European nations adopted side underride guards, beginning in the mid-1980's, and they were originally intended to stop bicyclists, motorcyclists, and pedestrians from becoming entrapped under the sides of trucks. Yet, such side guards have proven to also work well to stop cars from continuing beneath the sides of the large trucks and trailers.

In a typical case, the trailer is stretched across the road directly ahead... but in the dark of night, the tractor's headlights create a wall of glare that diminishes the oncoming driver's ability to perceive the trailer until it's too late to avoid underriding beneath and ripping off the upper half of the car. The trucking industry and NHTSA have both been negligently avoiding this side underride issue for over 30 long years... while the lethal side underride tragedies continue.

In the October 2000 trial of Maravilla versus Lufkin Industries, in Laredo, Texas, the jury found that the absence of any side underride guard on the Lufkin trailer was an unreasonably dangerous and defective design, and that Lufkin Industries had acted with malice, in disregard of public safety. Ricardo Maravilla had suffered fatal head injuries when his Ford penetrated beneath the tall side of the trailer. In the trial, Byron Bloch testified as an expert in truck underride and vehicle safety design, and he showed how a side underride guard was technically feasible and would have prevented the car from underriding beneath the tall, open side of the long Lufkin trailer. An article about this case appeared in U.S. News & World Report magazine.

|